Jeep JL/JT Quick-Release Front Inner Fenders

$319.95 – $559.95Price range: $319.95 through $559.95

Note: Product photos may contain optional components.

- Note: on 2024+ year models the passenger front inner fender liner runs into slight fitment issues. This can be resolved with minimal modification to the product or vehicle

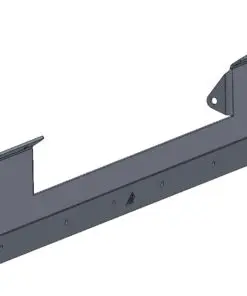

- Constructed from .060″ aluminum

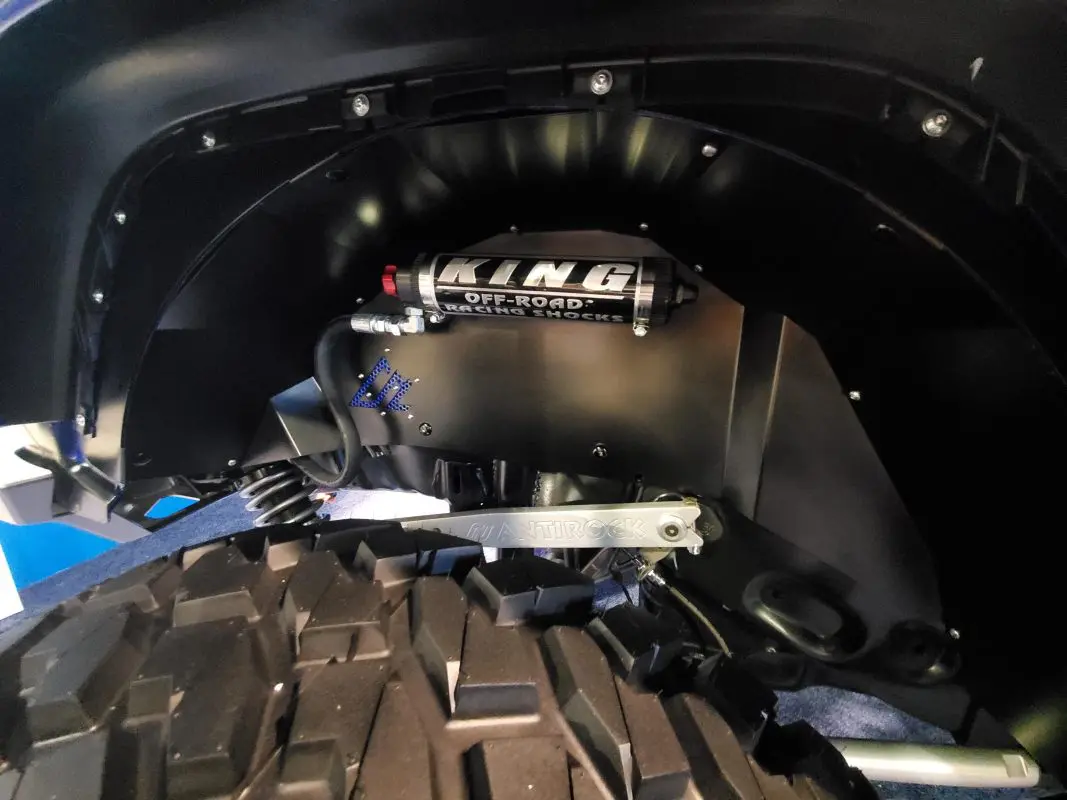

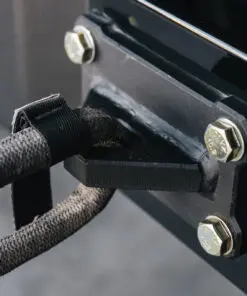

- Easily removes in about 30 seconds (per side) using quarter-turn “dzus” fasteners (for ease of cleaning and maintenance)

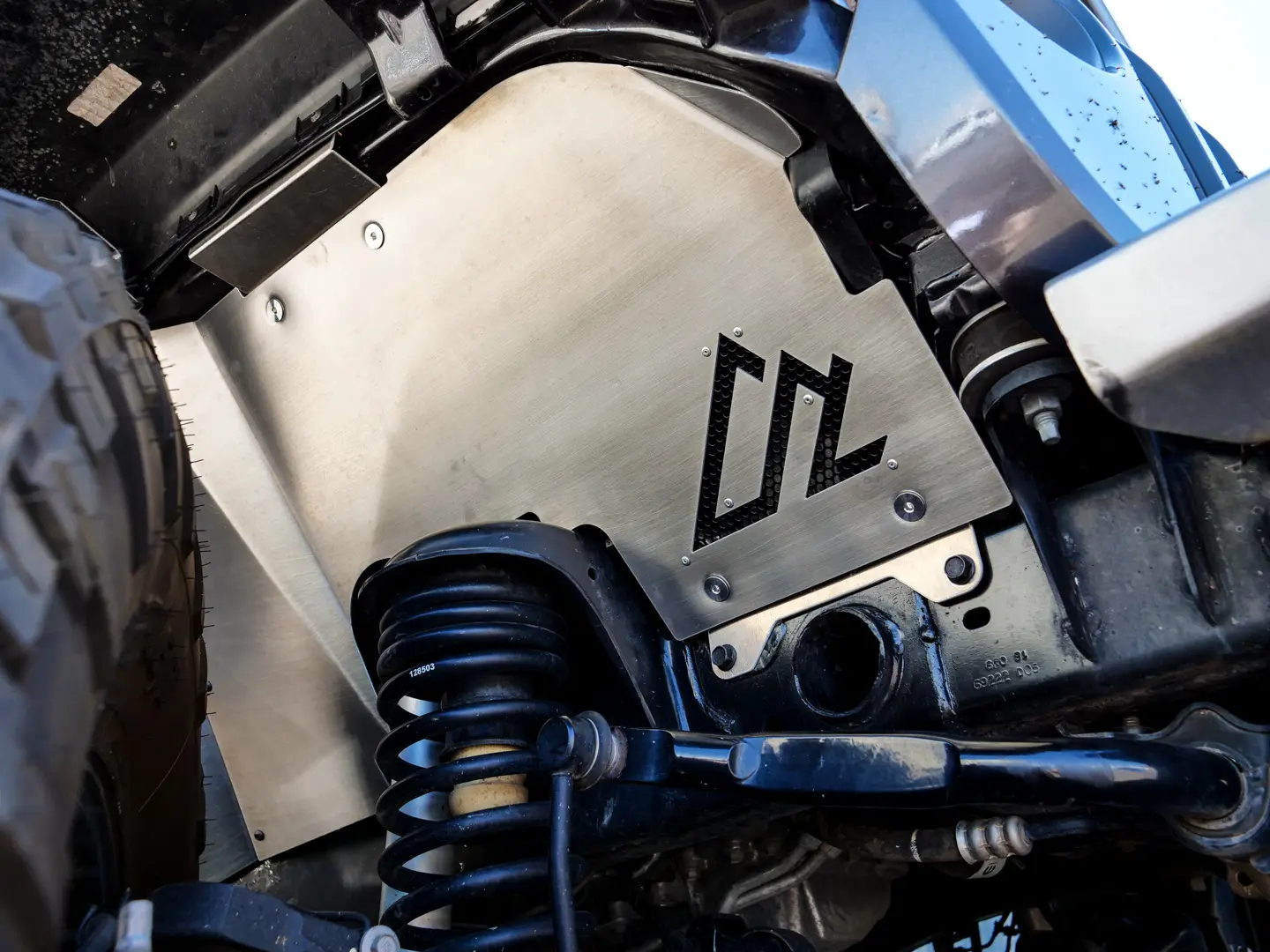

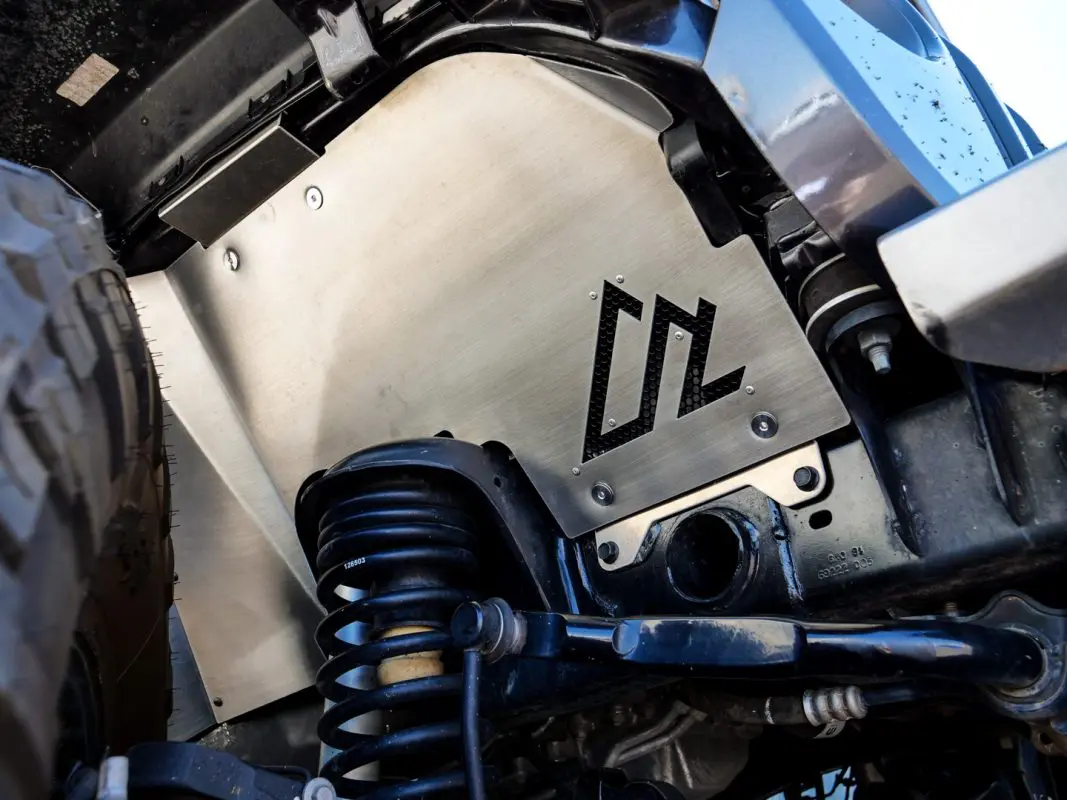

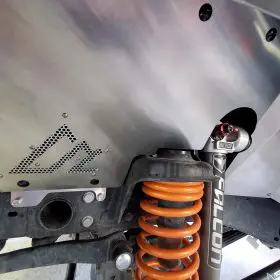

- Maximum coverage of vital engine and suspension components

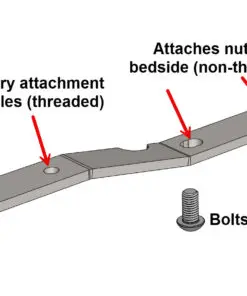

- Two-piece design (the two panels are connected with stainless bolts and nuts)

- No drilling required – these use ONLY factory holes

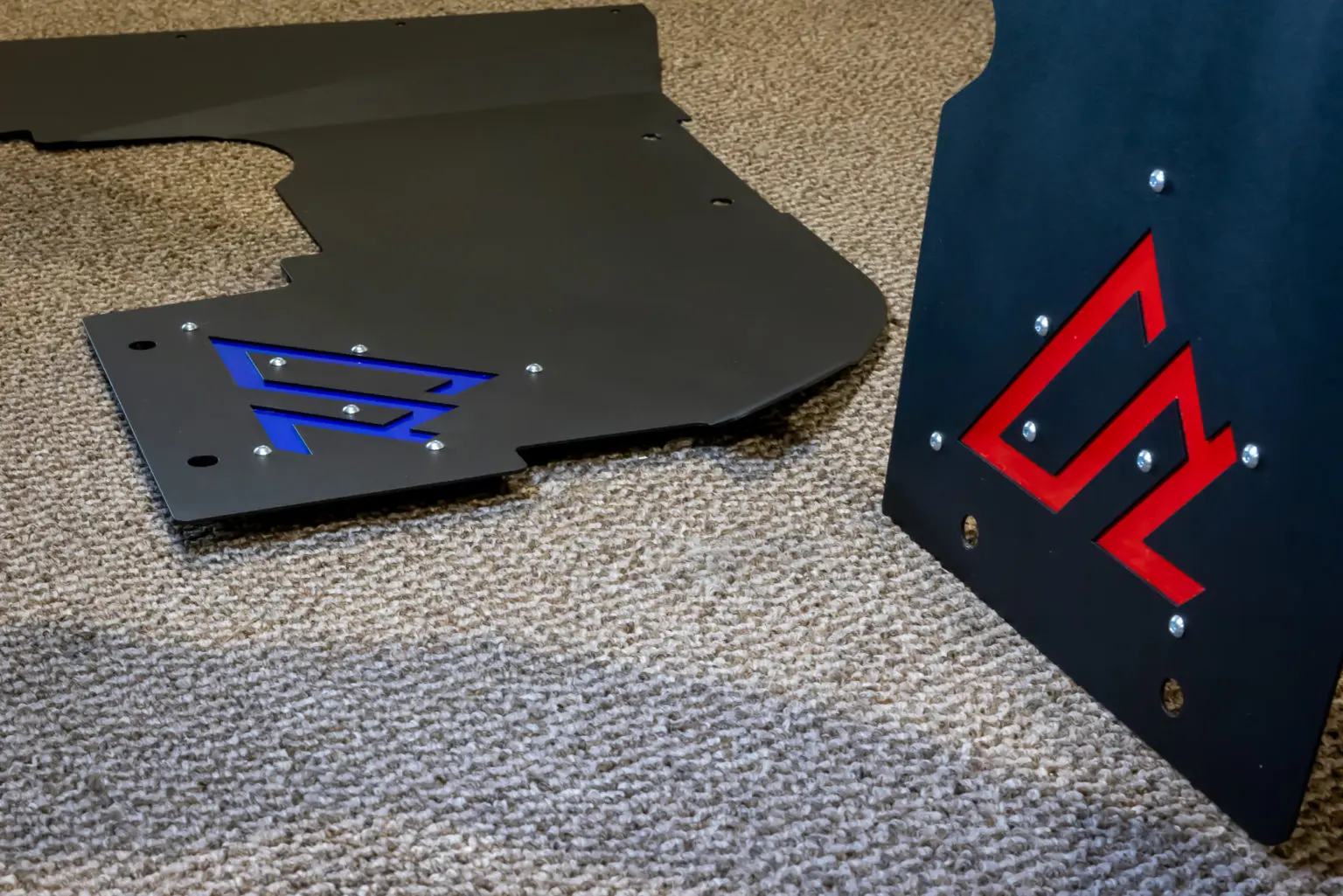

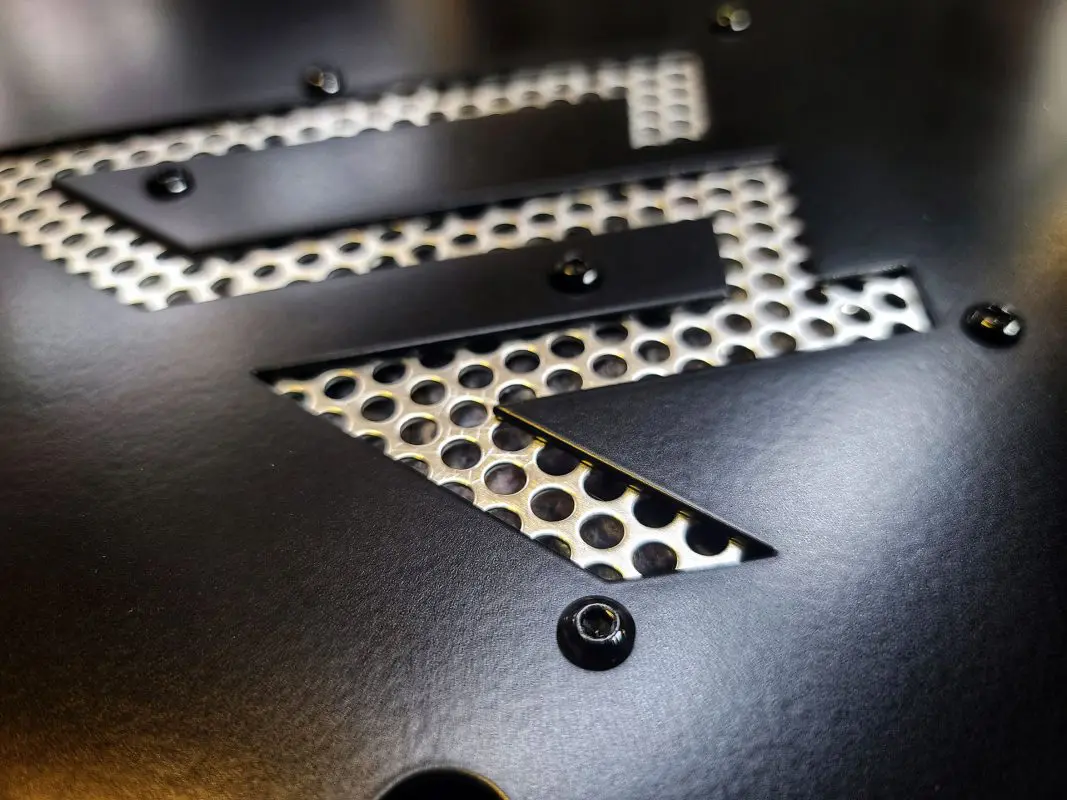

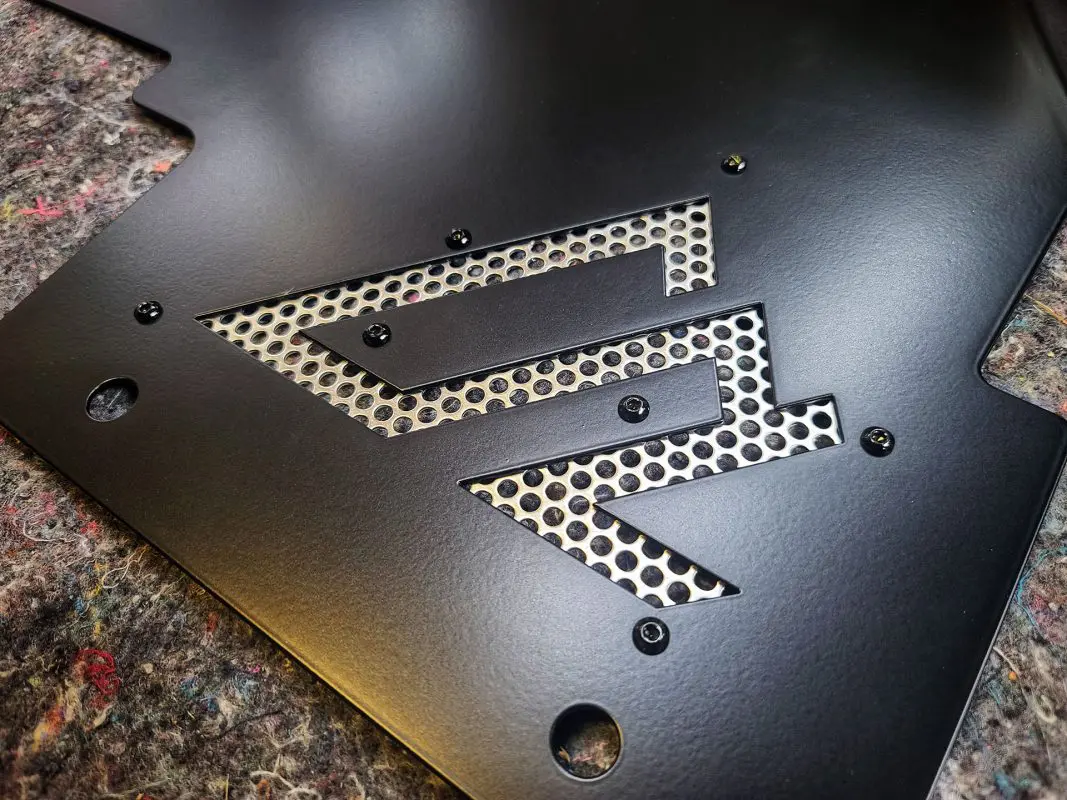

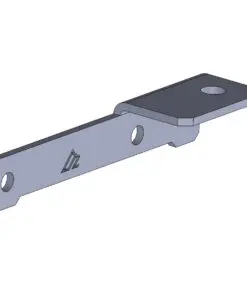

- Removable logo for easy color matching (attaches with stainless hardware – not as pictured in these photos)

- By default, these are shipped raw, uncoated aluminum. The logo plates are removable so you can coat/paint it the color of choice. The plates are aluminum so it is not necessary to powder coat or paint them.

- We are now using black aluminum dzus fasteners to better blend in with most coating options. I will update the product photos as soon as I’m able to get a set installed on a vehicle here.

Looking for the Full Setup?

If you plan to purchase the Front Inner Fenders together with the Rear Inner Fenders and our Next-Gen High-Lines, check out our Inner Fender and Next-Gen High-Line Bundle. Buying the bundle saves you $100 and ensures the most accurate shipping quote.

When products are added separately, the site can’t perfectly calculate the combined box size, which may cause the shipping estimate to be off. The bundle fixes this by letting us set the box dimensions as a whole—so you get the right shipping price up front and the best value overall.

Rear Inner Fenders

Same great quick-release function as the front. Available for:See our “Lead Time” page for current and estimated Lead Times.

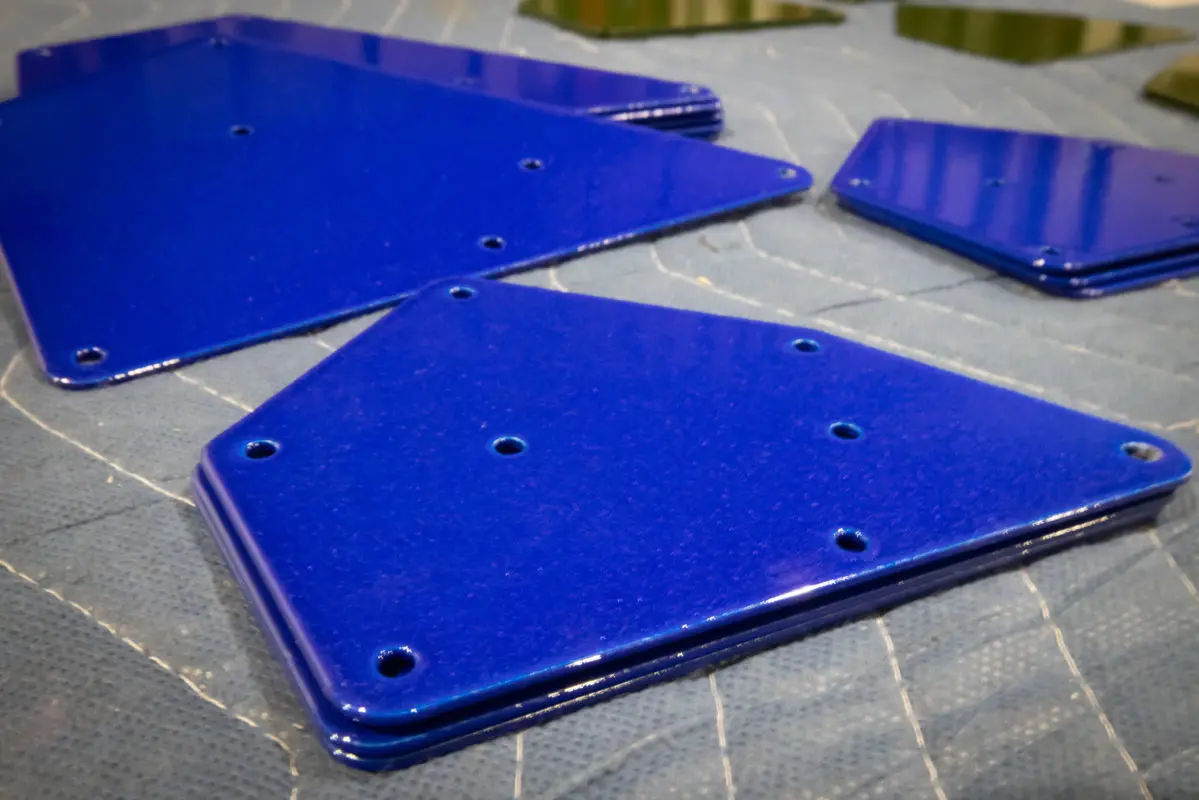

Important Powder Coating Note

Powder coating is a manual process done by humans and may take some time. When you purchase powder coated products from AAL, we coat them for your order. Occasionally, that means delays with non-standard colors, resprays for less-than-perfect conditions, etc. We have a very high standard with powder coated products. We will work to get your parts coated in the best condition possible before they leave the building. Please visit our Powder Coating Page for more info.Eco-Diesel

Important Note

The windshield washer fluid reservoir on the diesel JL/JT protrudes pretty far into the tire space of the driver’s side front wheel well. Our diesel-specific inner fenders are formed around this reservoir. However, with larger tires (ex. 39″ and above) the clearance between the tire and reservoir (even without inner fenders installed) is non existent when the axle flexes. For this reason, we don’t recommend running tires over 37″ on the diesel without relocating the windshield washer reservoir. After relocating the windshield washer fluid reservoir, you can run the non-diesel front inner fenders and avoid this clearance issue.Rear Inner Fenders

The wheel well design of the rear of the JL makes the Quick-Release system difficult to implement. Difficult, yes, but it is done now and we are very happy with the results. View Rear Inner FendersQuick-Release Demo

I’ll replace this video with a more professional, clearer version in the near future, but I wanted to show how quickly and easily they remove.Anodized Aluminum Hardware

By popular demand, we are now giving you the option of black anodized aluminum logo plate hardware. Thank you to all who have requested this as an option (these are not included unless selected above). We REALLY appreciate the feedback.

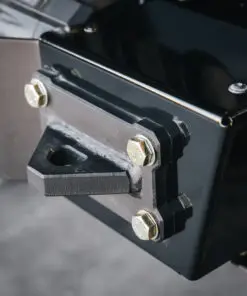

Allen Head ¼ Turn Fasteners

Our inner fenders use an industry exclusive quick removal process. This is accomplished with what is commonly referred to as a “Dzus Fastener”. William Dzus invented these little guys, now referred to as Quarter-Turn Fasteners. To make install and removal easier, we have chosen to use fasteners with an allen hex head.These are also available as a standalone product. Get Some Dzus FastenersFeatured on YouTube

It has been great to work with Britney and Kevin of LiteBrite. They were super helpful in debuting these inner fenders and our High-Line Fender Brackets at this year’s Easter Jeep Safari event. Take a peak at the video to the right to see their coverage of our products.Thanks, LiteBrite! We truly appreciate the partnership, very much.Custom Shock Cutouts

The intention of our custom shock cutouts is to maximize coverage on your expensive shock components, but still provide enough clearance for everything to flex properly.Raw/Unfinished –

Textured Black/Satin Black –

Other Color – Times may vary

See our “Lead Time” page for current and estimated Lead Times.

Featured in these Vehicle Builds

Frequently Asked Questions

Can you do a specialty shock cutout?

Yes, if you have shocks that are not listed, we can work on a custom cutout for you with a custom design fee and prefer to have the vehicle in the shop to complete the design. Without the shocks/vehicle in house, we can not guarantee perfect fitment.

Do I have to drill any holes?

All of our products utilize factory holes so you will not need to drill into your frame to install our products. You may have to clear out some holes in the body if there is build up from the paint.

Do I need retention hardware?

Yes, we recommend purchasing retention hardware with your front inner fenders, these only come with a partial kit. You will end up with extra hardware but it is better to have more substantial hardware in replacement of the plastic clips.

What are these made out of?

Both front and rears are made of .060” 5xxx series Aluminum. 5052 Grade Aluminum.

Do I need to powder coat them?

You can keep them Bare Aluminum if you would like, we just advise a clear coat if you plan on off-roading in muddy areas as aluminum can oxidize and stain. Keep in mind powder coating is done to order and could delay your order.

Related products

Cargo Management