Latest News

Why We Don’t Use Straps: The Engineering Behind the AAL Propane Mount

A different approach

If you’ve spent any time on the trails, you know the sound. It’s that rhythmic, metallic clank-clank-clank coming from the back of your rig every time you hit washboard terrain.

For most overlanders, that sound is the “soundtrack of anxiety.” Is it the jack? Is it the spare tire? Or – more concerningly – is it the 10lbs of pressurized propane you strapped to your tailgate?

Shop the CollectionWe spent weeks combing through threads on Bronco6G, JL Wrangler Forums, and Reddit, and the data confirms what we already suspected: Propane tank anxiety is real.

You don’t have to take our word for it. In this discussion on trail failures, users detailed exactly how traditional cam buckles loosen over washboard terrain. Another thread highlighted the frustration with bulky brackets that hit the vehicle body when the tailgate is opened.

One user described the feeling perfectly:

“I used to hear a pinging sound… I like to give it a couple of gentle slaps to confirm its sturdiness, maybe a verbal ‘that’s not going anywhere,’ but honestly, I’d rather have it secure than just hope the strap holds.”

At AAL, we don’t believe “hoping” is a valid engineering strategy. Here is why most generic mounts fail the durability test, and how we engineered the last propane mount you will ever need to buy.

The Problem: The “Strap-Snap” & The Rust Bleed

Most competitors build propane mounts the same way: a bent piece of mild steel and a generic nylon cam buckle strap. While this is cheap to manufacture, it presents three major failure points for the serious off-roader:

- Strap Stretch & Rot: Nylon straps are hydroscopic – they absorb water. When they get wet and then dry out in the sun, they expand and contract. Over time, UV exposure makes them brittle. We found countless horror stories of straps snapping on the trail, leaving drivers to use zip-ties or ratchet straps to limp home.

- The “Wiggle” Factor: A strap can only apply tension in one direction. It doesn’t prevent vertical oscillation. This micro-movement is what causes that annoying rattle.

- Rust Streaks: Most brackets are made of powder-coated mild steel. As soon as you slide a metal tank in and out a few times, you scratch the coating. The result? Rusty water streaking down the back of your $60,000 rig after the first rainstorm.

The Solution: Mechanical Retention & 5052 Aluminum

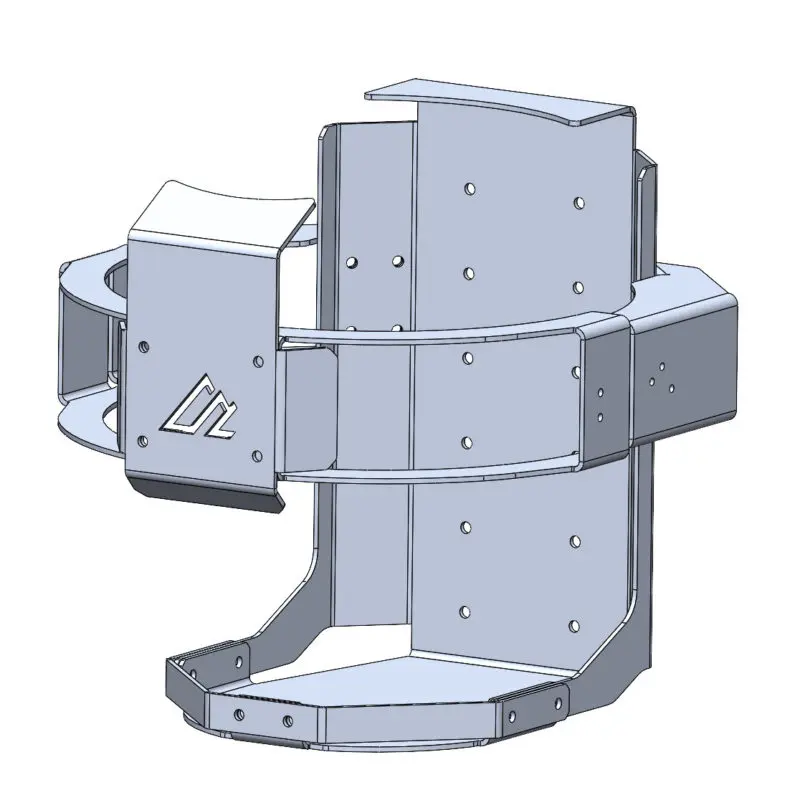

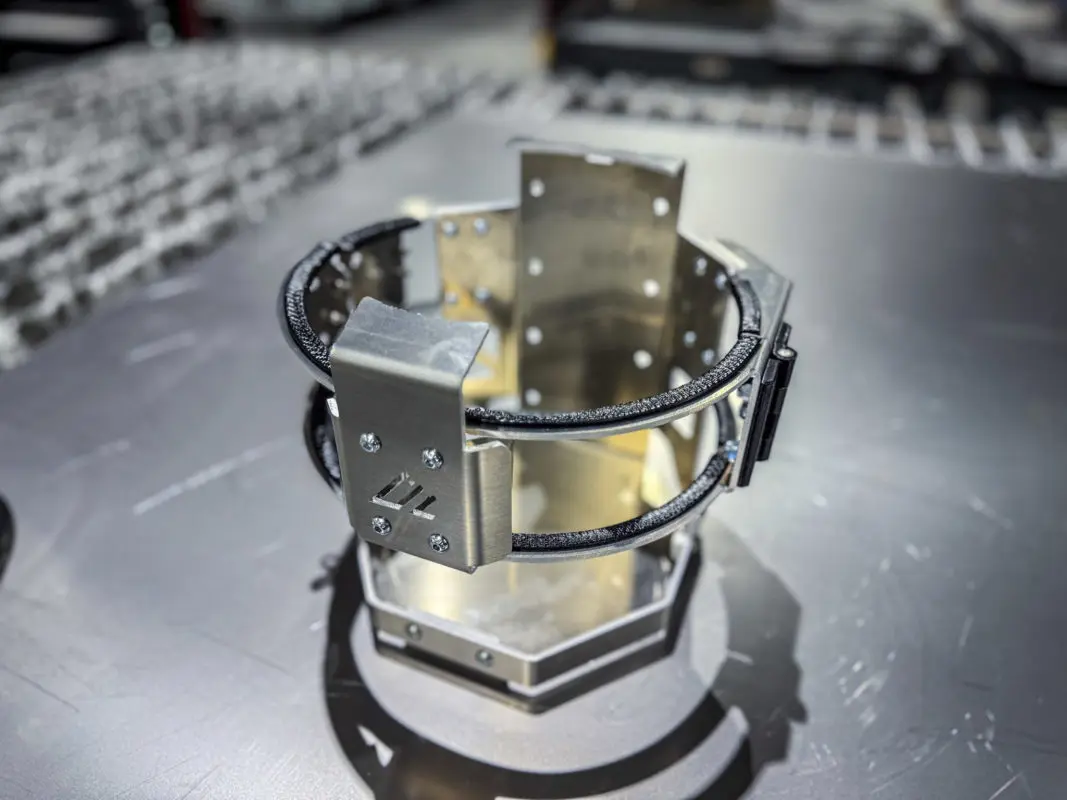

We designed the AAL Lightweight Propane Tank Mount to solve these specific mechanical frustrations. We didn’t want a “holder”; we wanted a locking system.

1. Zero-Wiggle Mechanical Latch

We eliminated the strap entirely. Instead, we use a stainless steel, quick-release draw latch.

- Why it matters: This latch applies consistent, high-pressure clamping force that doesn’t loosen with vibration or temperature changes. When you clamp it down, the tank becomes a solid part of the vehicle.

- The Benefit: Silence. No rattling, no pinging, no anxiety.

2. 5052 Aluminum Construction

We build every mount right here in St. George, Utah, using 5052 Aluminum.

- Why it matters: Aluminum is naturally corrosion-resistant. Even if you scratch it up (which you will, because you use your gear), it won’t rust.

- The Benefit: It keeps your rig looking professional and clean, while shaving critical weight off your build compared to heavy steel brackets.

3. The “Non-Marring” Grip

A common complaint we saw was metal-on-metal contact wearing holes in propane tanks. Our mounts feature edge molding (gate trim) and foam backing.

- Why it matters: This creates a friction grip that holds the tank tight without damaging the paint on the tank itself.

The Verdict

You didn’t build a high-performance vehicle to strap a rattle-trap to the back of it. If you are tired of retightening straps at every gas stop or scrubbing rust stains off your tailgate, it’s time to upgrade.

Shop the AAL Lightweight Propane Mount Collection

Available for 5lb, 10lb, 11lb, and 20lb tanks.